Single Chamber Orifice Meter

Description

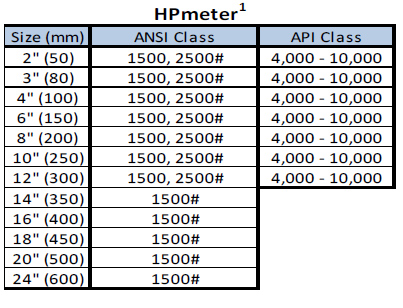

EPS meter1 TM / HPmeter1 TM (High Pressure) Single Chamber Orifice fittings are manufactured to meet stringent industry standards and safety guidelines and are designed to meet the end users expectations.

EPS meter1 TM / HPmeter1 TM (High Pressure) Single Chamber Orifice fittings are manufactured to meet stringent industry standards and safety guidelines and are designed to meet the end users expectations.

All our products are designed using DFM (Design For Manufacture) and DFA (Design For Assembly) techniques. This has resulted in products differentiated by their simplicity, reduced level of complex parts, and consequently provide the end user with a product that is remarkably simple to use, and is virtually maintenance free.

The “EPS HPmeter1" product range has been rationalised to the extent that we can offer significantly reduced lead times on this range.

The EPS meter1 TM / HPmeter1 TM single chamber orifice fittings can be installed into horizontal or vertical lines. Each product has been fully FEA (Finite Element Analysis) tested at design stage ensuring maximum safety to the user and the system. Upon product assembly, each product is fully pressure tested to satisfy industry safety, European pressure guidelines and product expectations.

The EPS meter1 TM / HPmeter1 TM single chamber orifice fittings can be installed into horizontal or vertical lines. Each product has been fully FEA (Finite Element Analysis) tested at design stage ensuring maximum safety to the user and the system. Upon product assembly, each product is fully pressure tested to satisfy industry safety, European pressure guidelines and product expectations.

Benefits

• High Accuracy, precision machined orifice fitting.

• Minimal maintenance required.

• Plate0 ® Quick release plate system that is impossible to install backwards

• Use of modern seals and simplest designs

• Field‐repairable

Design Codes

• ASME B31.8 Gas Transmission and Distribution Piping

• NACE MR‐01‐75

• ASME B31.1 Power Piping

• ASME B31.3 Liquid Petroleum Transportation Piping Systems

• PED 2014/68/EU – Pressure Equipment Directive

Measurement Standards

ISO 5167

API MPMS 14.3.2 (AGA Report No.3)

• High Accuracy, precision machined orifice fitting.

• Minimal maintenance required.

• Plate0 ® Quick release plate system that is impossible to install backwards

• Use of modern seals and simplest designs

• Field‐repairable

Design Codes

• ASME B31.8 Gas Transmission and Distribution Piping

• NACE MR‐01‐75

• ASME B31.1 Power Piping

• ASME B31.3 Liquid Petroleum Transportation Piping Systems

• PED 2014/68/EU – Pressure Equipment Directive

Measurement Standards

ISO 5167

API MPMS 14.3.2 (AGA Report No.3)

Options

• Exotic Materials for demanding service – Duplex, Inconel.

• High Pressure solutions

• Wide Temperature ranges.

• Stainless Internals as standard

• Meter Runs and accessories 6” 2500# HPmeter1 TM Single Chamber

• Bespoke design service available

Standard Materials of Construction

• Body Casting (150‐900#)– ASTM A352 LCC; ASTM A216 WCC; ASTM A216 WCB.

• Body Casting (1500‐2500#)– ASTM A487 4D

• Internal components – Stainless Steel 316

• Seals – Selected per application

• External Bolting – ASTM A194 L7 (HDG)

• Other materials are available upon request

Orifice Plates

The HPmeter1, meter1 and meter2 orifice fittings use industry standard orifice plate thicknesses as per the guidelines set out within ISO 5167 and API 14.3.

• Exotic Materials for demanding service – Duplex, Inconel.

• High Pressure solutions

• Wide Temperature ranges.

• Stainless Internals as standard

• Meter Runs and accessories 6” 2500# HPmeter1 TM Single Chamber

• Bespoke design service available

Standard Materials of Construction

• Body Casting (150‐900#)– ASTM A352 LCC; ASTM A216 WCC; ASTM A216 WCB.

• Body Casting (1500‐2500#)– ASTM A487 4D

• Internal components – Stainless Steel 316

• Seals – Selected per application

• External Bolting – ASTM A194 L7 (HDG)

• Other materials are available upon request

Orifice Plates

The HPmeter1, meter1 and meter2 orifice fittings use industry standard orifice plate thicknesses as per the guidelines set out within ISO 5167 and API 14.3.

Body Configurations

Flange x Flange, Flange x Weld or Weld x Weld

FF (Flat Face), RF (Raised Face), RTJ (Ring TypeJoint)

Flanges available in the following formats:

• ANSI 16.5, 16.47

• Techlok & SPO

• Graylok

• API 6A

Maximising the meter1 TM/ HPmeter1 TM

• Orifice fitting with Meter Tube including straightening vane/profiler

• DP transmitters and Process Transmitters

• Flow Computer and Enclosure

Flange x Flange, Flange x Weld or Weld x Weld

FF (Flat Face), RF (Raised Face), RTJ (Ring TypeJoint)

Flanges available in the following formats:

• ANSI 16.5, 16.47

• Techlok & SPO

• Graylok

• API 6A

Maximising the meter1 TM/ HPmeter1 TM

To ensure absolute metering accuracy, it is recommended that meter tubes are purchased and manufactured to complement the orifice fitting. This ensures concentricity between the pipe and the fitting, and eliminates uncertainties associated with misalignment. LEADING can supply the following items for a complete metering solution;

• Orifice fitting with Meter Tube including straightening vane/profiler

• DP transmitters and Process Transmitters

• Flow Computer and Enclosure

Let’s get started

Are you looking for our EPS products?

Stop worrying about technology problems. Focus on your business.

Let us provide the support you deserve.